Manage Suppliers with Precision

Let’s talk about construction and EPC supplier management and how to get visibility into bidder milestones. The purpose of this is to show you how integrating suppliers into your process and your system, you can gain visibility into what bidders are doing, but more than that, you can gain the right amount of visibility, so, if you have sealed bid situations, you can respect those.

First, let’s talk about some of the problems, some of the systemic, environmental, and situational issues that buyers face. Then, let’s solve those problems.

What does a successful procurement operation look like? There are many metrics that tell the tale, but there are time-to-PO, schedules, budgets, technical requirements, commercial requirements, cash flow requirements, among others that need to be met.

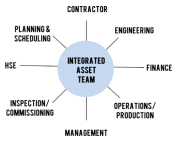

How does a procurement operation achieve success in these categories which ultimately leads to a successful procurement operation? The answer is that they integrate teams with teams (clients, engineering, suppliers, buyers, logistics, quality surveillance, construction, etc.) and connect those teams with current, useful information. A huge part of being successful is managing suppliers through controlled, pointed interactions and the appropriate level of visibility into supplier progress.

What does a successful supplier interface look like? With every procurement organization, there’s a slightly different process. Suppliers have to adapt to those processes for everybody that they do business with. Oftentimes it’s confusing and they’re slow to adapt and slow to move. You don’t always get back exactly what you want, or suppliers submit things in different formats. It is important to mitigate this by integrating the suppliers into the buyers system – whatever that means to you.

Yes, suppliers and buyers are using the same system. Buyers and suppliers really shouldn’t communicate or exchange information via email. They should use the communication tools within their system or application that they’re using to interface. All of that communication needs to be logged the PO. If there is outside emails or phone calls, all of that needs to be systematically logged to the PO so it can be reviewed and that communication doesn’t get lost, because that can cause problems down the road and be pretty ugly.

There also needs to be visibility. The buyers need to be able to see progress that the suppliers are making. The buyers need to be able to identify and resolve issues in a timely manner. We’ll take a look at that, like no-bid situations, why has a supplier returned a no-bid disposition on a requisition. Oftentimes, it’s for something simple, and they can go and make some changes and resubmit that bid out, and get that supplier back in the ball game.

When you add visibility to the process, you run into some problems here and there. One of them that we hear a lot is respecting sealed bid situations. How can you track what the suppliers are doing on their end, and how they’re interfacing with your application while still maintaining the sealed bid and not viewing prices and so forth. How you do that is by tracking certain milestones.

Finally, the last part of a successful supplier interface, is buyers need to be able to report on late action and other metrics that they can gather form the suppliers, so they can ultimately rate the suppliers and figure out if they are good to do business with or not, in the future.

Let’s take a look at how ProjecTools manages this process. On the buyer’s side, they have their own workflow that they run the RFQs through. They take the technical documents and commercial requirements and they package that together in ProjecTools application. Then, they issue it to the bidder. This sends it out to the supplier page where the suppliers pick it up.

It’s important to note here that there’s a workflow on the supplier page that the suppliers must follow. They would have to acknowledge the bid that they’re working on. They’d have to view and download the technical and commercial documents before they enter an intent to bid. If they enter a no-bid, they’re going to have to tell you why. If they say they are going to bid, they’re going to have to tell you when.

Similarly, before they actually enter their bid and save and submit it, they’re going to have to achieve all the steps that you see here before. We can see here that there’s a line and an arrow on the screen that points to tracking on the buyer’s side. It’s important for the buyers to have visibility into what the suppliers are doing and see all of these milestones reflected back on the buyer’s side. The buyers need to know that suppliers have acknowledged a bid, so they have at least looked at it, and that they’ve viewed technical and commercial documents, and they have entered an intent to bid, and told you what date they’re going to get that in, or entered a no bid and told you why. Maybe you can get them back in the ball game, like I said. That’s a good way for buyers to manage that process and maintain some visibility without seeing the actual numbers that are coming back until the bid is unsealed.

Number four is the bidder view and comparison. Now, I’m going to take you into the application, and I’m going to show you how to track bids. I’m going to prove to you that ProjecTools will get your suppliers working in your system, and it will provide online access to the buyers and the suppliers, and it maintains a reasonable workflow that shows buyers when key milestones get hit or missed.

Let me drag over my screen here. This is in ProjecTools requisition manager, this is on the buyers side that we’re looking at here. We’re looking at a requisition for pressure relief valves. This has been issued to bidders. I can see the bidders that it’s gone out to here. I can see that, for instance, ABC Manufacturing has acknowledged the bid and indicated a no-bid status for whatever reason. I can actually go see that in here. I can actually see the reason in here. I can mitigate that problem, if possible, or respect it if it’s unattainable, or if I’m not able to overcome it.

Let’s go in and take a look at what the suppliers see. Then, we’ll come back in here, and I’ll show you what tracking the workflow looks like. Let’s go log into the supplier side as ACME B Supplier. Here, we have the supplier page. We can see that I have an incomplete task, this RFQ. We’ll open it up and we’ll see some basic information, when is this due? Big information here, when is this due? What is the requisition for? Then, there’s some various things that I talked about here, such as that bidder acknowledgment, notes to bidder, the technical and commercial documents, and the bidder intention, and entering in price for the different line items, and so forth.

Real quick, let’s just try and download a document. ProjecTools workflow says that this supplier needs to submit an acknowledgment to this RFQ before they download any documents. This is important because the buyers need to know that the supplier is actually in here looking at this. The supplier acknowledges the requisition, and now they can download the documents. Similarly, I mentioned the bid intentions here. If the supplier declines to submit a quote, they can indicate so here and tell the buyers why. This will flow back to the buyer portal that I was showing you earlier. Similarly, if they say that they are going to bid on this, they’ll have to enter in the date so the buyers know when to expect that bid to come in. Now that we’ve followed the workflow here, we’re acknowledged, we’ve downloaded the documents, and we’ve submitted an intent to bid, we can actually now go enter in some line items and prices.

Okay, so let’s ow log in as the buyer here, again. Here I am now in the buyer’s portal. I see that this is a little bit different. I can see that Acme B Suppliers, who I was just logged in as on the supplier side, that they have acknowledged this particular RFQ, and that they have submitted an acknowledgement of the receipt, and they did it on the 26th of February. Had I submitted the bid, I would have seen the date that it was submitted here. After all the bids are submitted and this is unsealed, this would be available, this would show the price and when it was valid through, and any specific terms and so forth that were submitted back from the supplier, right in here.

ProjecTools Product Information

ProjecTools Client Spotlight

ProjecTools Client Spotlight "I don't see how companies can manage projects like [...]

Standard Project Management Features

ProjecTools subscriptions provide valuable standard features that support projects. ProjecTools standard features are available to each user to complement core application functions and business processes. Utilize the modules below to increase top-down visibility, communication, accountability

Security and Reliability

Users need a secure, reliable environment to access project information and perform work. All applications and client data resides in a private cloud network with data replication and failover to geographically diverse datacenter equipment. ProjecTools provides 99.5% Network Availability

Construction Project Management Services

ProjecTeams is proven for flexible on-site or remote project deployments. Each ProjecTeam specialist has deep work history with a career of improving project execution, information management processes, with tools that make projects efficient, timely, and profitable.

ProjecTools Resources

Spreadsheets and Email as Project Management Tools

Projects have too many moving parts and too many players to be trusting critical data to spreadsheets and emails. You need a spreadsheet reduction strategy.

Project Management Assessment

Project Management Assessment Assess your project management practices against the best project execution teams in the Capital Construction, [...]

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Aligning Document Control and Cost Control

Align Document Control with Cost Control and create seamless progress and earned value reports to stay on budget and improve cash flows.

ProjecTools Videos, Demos, and Webinars

Optimizing Review and Approval Processes for Engineering

Let’s talk about review and approvals, and closed-loop systems, and how to execute the review and approval processes for engineering and commercial...

The Keys to Successful Document Management

Let's talk specifically about document management software, and the key factors for clean and organized documentation, accessibility, finding a system...

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Document Distribution and Access for EPC and Construction

Global projects have global teams that need to be in the loop. Cloud technology takes the pain out of giving teams on demand access to project data.