Procurement Management Boot Camp

Welcome to the Procurement Boot Camp. We are going to talk about some things you can do today, to shape up your procurement operation, and make sure you are ready to kick some butt in the coming year.

So first it is going to be beneficial to identify some things that a lot of procurement groups don’t quite get right. Let’s get into that first, and then we will go into some things he can do to remedy those problems, and really dig into the boot camp.

Welcome to the Procurement Boot Camp. We are going to talk about some things you can do today, to shape up your procurement operation, and make sure you are ready to kick some butt in the coming year.

So first it is going to be beneficial to identify some things that a lot of procurement groups don’t quite get right. Let’s get into that first, and then we will go into some things he can do to remedy those problems, and really dig into the boot camp.

As far as the problems in procurement right now, it’s just a really tough environment. It’s very price-focused climate, all you hear from the top is cut costs, cut costs, cut costs. Especially if you are in some uncertain industries right now. Like some of our clients are in oil and gas. They are hitting their vendors hard, and they are hitting systems hard, and it’s affecting their ability to maintain a relationship with their suppliers and it’s affecting the buyer’s moral and ability to execute. It’s hard to keep functioning at a high level, when you are just focused on price rather than value. So that is one problem.

Another problem that procurement groups run into, is that they are hearing that time-to-PO is too long. They are taking too long to get the information from engineers, legal, clients, and suppliers to assemble the requisition, and run it through the commercial review and approvals. The bottom line is that the building of the procurement package, and cutting the PO is just taking too long.

We are also hearing that PO development is too labor intensive. This is true, and it is mostly because of some stuff that we are going to talk about following this. Really the keys to reducing labor on building out your requisitions is standardizing and making repeatable process, getting everybody working together in a system, and making sure teams are accountable. If you can supply your buyers, or your buyer team, with tools or a method make all those things happen, the labor per PO is going to go way down, and you are going to be cutting POs way quicker. Your procurement team is going to add a lot more value to your company.

Some problems that cause the first three here. We see all the time that some procurement teams are constantly rewriting the book with what they are doing. They will cut one PO and feel really great about it, and then they will go work on another requisition, and they will basically start from scratch, maybe reuse a couple of things if they can find it. If they can find the last spreadsheet with the terms and standard lists and all that stuff, they will use it. This isn’t a good repeatable process. A repeatable process uses category specific templates and a pre-defined workflow for processing a requisition according to category.

Another problem is the inability to commit to standards and templates. All of these you see probably relate to each other, but when you commit to standards and templates, you are not constantly rewriting the book because you have standards and templates that you can draw from and develop your requisitions quicker, and get them out the door quicker, and make sure that you didn’t miss anything very important and critical.

Another problem is siloed teams and information. If teams aren’t communicating effectively one doesn’t really know what the other is doing. This is an age old business problem: siloed teams can’t work together, they are off in their own areas, doing their own thing, just really hoping for the best. With the amount of information that we have in the business world now, information is the same way. If these groups that are over here doing their own things, have their own big, vast silos of information, and the other teams that need them can’t get to them. A great example here for the procurement boot camp, is if your engineering team has all this detailed technical data that you are going to need for your requisition, but you have no way to access it, other than picking up the phone, or shooting an email, or sending a smoke signal. That is not an integrated situation. That is siloed information, and that is not going to help you guys cut POs quicker, or reduce labor, or add more value.

The following problem here, is non-integrated data and applications. Your data is very important, and having visibility in your data is what allows you to make, good, logical decisions in the procurement world. Not being able to see the full picture will all of the data in one place, you are operating at a disadvantage. It is a huge problem.

The next problem that we see all the time in the procurement world, is that suppliers give us the runaround. They are generally pretty slippery. They could be on the other side of the world, they could be speaking your language as their second or third language. It’s just hard to keep on track and have some visibility into their progress, what they are doing, and how they are adding value to your procurement operation. If you can prevent your suppliers from giving you the runaround, you are going to have a massive advantage going forward.

Another very common problem is numbering confusion, revision confusion, and all that. This really speaks to your internal process. How developed is your internal process, do you have standard numbers? How do you maintain revisions? How do you know which requisition revision is the latest? Do you even use requisition revisions? These are all questions you need to ask yourself, and evaluate how you are doing it, and wonder if there is a better way. Even the most robust, and established procurement operations, even world class operations, they have room for improvement here as far as standardizing your conventions and process and optimizing that process.

The next one here is exporting PO information to a spreadsheet and sending it to Quality Surveillance. This speaks back to the integration of your applications. There is kind of a two parter here. Do you have a procurement application that is going to manage your quality inspections? If you do, how are you going to get that PO information over there to that system? Do you send a spreadsheet, do you just call them up and say “We have cut this PO, here are the PO dates and delivery dates that we have agreed upon” or maybe even set a meeting to communicate this information. I put these up here because these are very typical things, send around spreadsheets, calling people, or setting a meeting to just update people on status, and need dates, and where you are at. I view these activities as a waste of time – or put more delicately – room for improvement.

There are certainly better ways to this, and it all centers around tools, processes, and teams. If you have the right team members, with the right ideas on how to run procurement, and the right tools to implement those ideas, and get these teams working together, you are going to be at a massive advantage in the procurement world going forward. I heard this the other day, when I was on a call with a prospective client, and he said procurement teams without the right tools, spin their wheels, eat profit, and make themselves miserable with stress, frustration and uncertainty. That rung with me, and I put it in here because it is true. If your very talented buyer teams, are going into the process without the right tools, and processes, they are going to spin their wheels, and that is going to eat profit, and your teams are going to be miserable, frustrated, stressed out, and they are not going to know what is going on possibly in their own department, and certainly not in other departments if applications aren’t integrated and you don’t have regular communication protocols.

Now that we have identified the problems, let’s get into boot camp mode and see how we can fix them. The first thing you should work on right now is you need to get your suppliers working in your system. This gives you an incredible advantage being able to have visibility into what your suppliers are doing, and the progress they are making on your products. You can also gain insight into and pull metrics from what they are doing and rate your suppliers quantitatively.

The next thing you want to do is standardize and enforce your lists, your numbering, your categories, your workflows, etc. You want to define your process, because if you don’t define your process, there is no way to improve it if it is not documented. Once you define your process. Whatever the process is at first is fine as long as you can define it, standardize it, and enforce it. The problems are going to rear their head with your process, and then you can go about fixing them in a logical, assertive, positive way.

The third thing to do, is to eliminate silos and disconnected systems. Like we talked about earlier, you don’t want to have teams that are separated and can’t communicate with each other, and use the different groups data to their advantage. Starting around 2006 and on there is no reason that we should be hiding data from folks critical to our projects that it could definitely benefit. Especially if they work in the same company as you.

The fourth thing that you really ought to think about is using a task based system that will maintain accountability and reduce confusion. There is a few parts to this. A task based system means that chunks are built up by the procurement staff, and send out to the authorities, the reviewers and approvers, in a nice contained little online task, that they can go in, and complete, and notes to, and send back to the system with a clear disposition on what needs to be done. This will maintain the course and the schedule, and provide a clear path to move that requisition forward, and eventually become the PO that is going to make you guys a bunch of money, and get delivered on time, and operate beautifully.

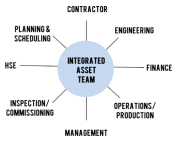

ProjecTools, we actually have an application that does this, and we have an application that does this incredibly well. It was really built around standardizing your procurement framework, your templates, your lists, and your categories, and all of that. Building a workflow that matches your process, and will really enhance your deliverables. Number two is, it gets your suppliers and your subs working in your system, in a very coherent way that adds visibility and accountability. Number three, ProjecTools integrates with other applications. It integrates with our document application, our cost application. It integrates with scheduling and quality surveillance, and logistics. It also integrates with equipment manager, so your engineering can actually feed your commercial teams on the procurement side. Number four, ProjecTools provides accountability, and visibility so thing get done, they get done on time, and if they don’t get done on time, or in the correct manner, you can go in and see what happened and report on performance. It is very important to have each of these, to remain competitive in this environment and elevate the conversation past cost to value.

ProjecTools Product Information

ProjecTools Client Spotlight

ProjecTools Client Spotlight "I don't see how companies can manage projects like [...]

Standard Project Management Features

ProjecTools subscriptions provide valuable standard features that support projects. ProjecTools standard features are available to each user to complement core application functions and business processes. Utilize the modules below to increase top-down visibility, communication, accountability

Security and Reliability

Users need a secure, reliable environment to access project information and perform work. All applications and client data resides in a private cloud network with data replication and failover to geographically diverse datacenter equipment. ProjecTools provides 99.5% Network Availability

Construction Project Management Services

ProjecTeams is proven for flexible on-site or remote project deployments. Each ProjecTeam specialist has deep work history with a career of improving project execution, information management processes, with tools that make projects efficient, timely, and profitable.

ProjecTools Resources

Spreadsheets and Email as Project Management Tools

Projects have too many moving parts and too many players to be trusting critical data to spreadsheets and emails. You need a spreadsheet reduction strategy.

Project Management Assessment

Project Management Assessment Assess your project management practices against the best project execution teams in the Capital Construction, [...]

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Aligning Document Control and Cost Control

Align Document Control with Cost Control and create seamless progress and earned value reports to stay on budget and improve cash flows.

ProjecTools Videos, Demos, and Webinars

Optimizing Review and Approval Processes for Engineering

Let’s talk about review and approvals, and closed-loop systems, and how to execute the review and approval processes for engineering and commercial...

The Keys to Successful Document Management

Let's talk specifically about document management software, and the key factors for clean and organized documentation, accessibility, finding a system...

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Document Distribution and Access for EPC and Construction

Global projects have global teams that need to be in the loop. Cloud technology takes the pain out of giving teams on demand access to project data.