Align Quality Surveillance and PO Inspectors

See how ProjecTools integrated, cloud-based software platform helps Oil and Gas, EPC, and Capital Construction companies align Quality Surveillance and PO Inspectors.

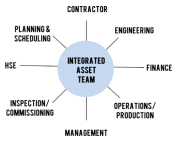

One of the last steps for ensuring quality in the supply chain is quality surveillance. The buyers have corralled technical specifications, commercial terms, buyer notes, and supplier feedback to execute the order – the remaining falls on the quality surveillance team. The quality surveillance team coordinates inspections of quuipment or assets that are being purchased or built. Given the global nature of today’s supply chains these on-site inspections can take place anywhere in the world, which complicates things for the Quality surveillance coordinators and the PO Inspectors.

To actually align quality surveillance and PO inspectors, you have to look at and pointedly address some key challenges. PO Inspectors need easy access to technical documents, line items, schedules, and inspection plans. They also need a convenient medium to access these items and log site visit reports, time, mileage, expenses, etc. The Quality Surveillance Teams need visibility into inspector activities to control budgets and ensure sufficient progress is being made. They also need timely feedback from inspectors so they can manage issues or escalate them to the proper channels.

ProjecTools Quality Surveillance Software Application helps coordinate pointed PO Inspection plans and arms PO inspectors with the technical documents and forms they need. See for yourself in the video above how the app aligns quality surveillance teams and PO inspectors, reduces inspection turnaround times, and closes the loop in a way that emails and spreadsheets never will.

Let’s talk about how ProjecTools will align your PO Inspectors with your Quality Surveillance Teams using a very nifty online portal that will get your PO Inspectors inspecting the right equipment at the right time and have the right supporting materials to perform those inspections all in a very convenient online portal.

First I’m going to go through a couple slides here. We’re going to talk about the problems. Why you need to align PO Inspectors. What that landscape looks like in the current software market. Then we’re actually going to go into the application. I’ll show you what the PO Inspectors see and what the Quality Surveillance Team sees. How the Quality Surveillance Teams can coordinate alignment with their PO Inspectors.

When we talked about quality surveillance for EPC, they’re telling us it’s very difficult to manage. They’re saying PO Inspectors are often on the other side of the world. If you’re running a shop here in Houston and your Inspectors are in Korea, they’re difficult to manage. They’re acting on their own. They’re interfacing with suppliers. Worse case scenario, they’re asking suppliers for engineering and technical documents. Even worse case scenario actually, you’re having to send a flash drive with all the documents that they need to perform their inspections via the mail. They don’t have instant access to information a lot of times. They’re having a tough time performing their inspections.

Quality Surveillance Teams are also telling us that it’s hard to plan for, budget, and coordinate the PO Inspections. This is just a logistics thing. If you’re using e-mails and spreadsheets to define your inspections and coordinate these things, chances are things are getting lost in the mix. The inspections are coming back late, incomplete, or what have you.

Another thing we’re hearing is that PO Inspectors don’t have on demand access to the right documents and forms so they’re sitting idle. This goes back to those thumb drives and e-mails asking suppliers for information. That’s just not the way you want your PO Inspectors to operate. We’re also hearing that most Quality Surveillance Management Tools are incomplete. They don’t provide closed loops and paper trails. Really what this means here is that there’s no portal where the site visit reports are submitted directly back to Quality Surveillance for processing. When the loop isn’t closed like that, you’re forced to rely on e-mails which get lost, which don’t get sent. It can end up being a real nightmare.

How does ProjecTools contribute to solving these problems? Number one, ProjecTools will get your Quality Surveillance Team and your Inspectors working in the same system to close those loops. Number two, ProjecTools will help you use an optimized EPC or oil and gas eccentric work flow to manage your onsite inspection process. Three, ProjecTools are going to provide a single place for Inspectors to find documents and log results. There’s no confusion on their end. It’s really simple. Number four, accountability and visibility is built in. As with everything in ProjecTools, you can see who did it and when they did it. You can report on it which is super key. I’m going to go through each one of these points in a little bit greater detail. Right before we get into the demo.

The first thing I mentioned, Quality Surveillance Teams and Inspectors working on one system. ProjecTools is a cloud based application. Whether you’re a coordinator, inspector, document controller, or [inaudible 00:03:26] member for that matter. You’re logging in through the same application. Through ProjecTools website. You get access to your companies information through a web based interface. ProjecTools provides quick and robust searching so you can quickly find what you’re looking for. No sifting through spread sheets, e-mails, and file structures, pulling your hair out. None of that. There’s also role based permission. You can provide access to your team without sacrificing security. We have that inspector integration, a special web portal just for them so they can perform their on site inspection.

Number two that I mentioned was the optimized EPC work flow. ProjecTools allows you to enforce and automate the right work flow for you quality inspections. There’s an application task and task management so data’s in one place. It’s archived and it’s re portable. Tasks go out to individuals rather than teams. Accountability lies with individuals rather than groups. This is very important for maintaining alignment once you’ve established it. Additionally there’s some integrated time and expense tools in here so your PO Inspectors can align themselves with your budget. They can log time, mileage, and expenses, specific reports so you can keep those under control.

Third, I mentioned there’s easy access to information. As I said, it’s an on line tools. Inspectors from around the globe can log in and see their technical documents and their inspections. When they access documents, they’re going to get the latest rev every time. The document management module’s going to publish a rev see here. If they click on the document, it’s automatically going to pull up the latest publisher vision. With the document distribution matrix in ProjecTools, inspectors have a second way to access the documents and forms that they need. They can also have access to the un-priced PO. They can really see the pertinent PO information. What’s in the agreement that they need to be inspecting and things to look for without seeing some of the more commercial terms like prices. Real time site visit reports. Once your PO Inspector submits the report, clicks go, it’s immediately available for the Quality Surveillance Team.

Accountability. We touched on this a little bit earlier. Everything in ProjecTools is user based. Tasks are directed to specific inspectors and PO coordinators rather than the group. Their are notifications and due dates so you can help enforce progress. Your PO Inspectors can log concerns which get logged directly into supplier manager module. They can log concerns, corrective action reports, etc.. Your Quality Surveillance Team can report pretty much everything that’s done. They can main detailed records [inaudible 00:06:11]. See where they need to follow up. Hold people accountable.

Now let’s look into the app. I’ll actually show you guys how ProjecTools quality surveillance works. Really what I want to do here is I want to prove that ProjecTools aligns your Quality Surveillance Team and Inspectors by getting them working in the same system with an optimized EPC work flow and providing a single place for Inspectors to find documents and log results. You guys are seeing my ProjecTools application portal. This is where your Quality Surveillance coordinators are going to go. Set up the Inspection portals for your Inspectors. As you can see here we have some PO’s set up, options. You can plan your PO Inspections. You can set start dates, complete dates, add planning notes, and very important, you can attach a budget to this. You set up a budget. When the Inspectors log costs or expenses against your budget, they show up here as actual so your Quality Surveillance Team can know what’s going on and keep the process under control. Additionally in here, you can log needs, schedule calls, and activities, and run approval processes. You know that the process you set up is acceptable for the PO or the project.

Over here under the coordination tab this is all very simple stuff. The coordinators can schedule calls, assign Inspectors. They can define activities. Issue work assignments and then log those assignments. Quality Surveillance Inspectors will feel very at home in a module that’s this simple and this straight forward. What we’re really talking about today is aligning the PO Inspectors. We’re going to spend a little bit more time in the PO Inspection portal. I’m going to go right here. This is the application home page. Your Quality Surveillance Inspectors when they log in, they’re going to see an interface very similar to this. Over here on the left hand side, they’ll find their My PO Inspections. Within this screen they’ll see all of the PO’s their assigned to inspect. Every piece of equipment here that me, as an Inspector needs to be paying attention to is going to be on this screen.

We’re going to take a look at this platform Pump Skid. Right off the bat as an Inspector I know that all the pertinent for this particular screen. I know the PO number. The supplier. The date the PO was cut. What project it’s for. Brief description and what the Inspector is. I know the Inspectors name says Mark. Within the screen for this particular PO I can see the un-priced PO, supplier contact information, who should I be talking to when I’m on site. Who’s going to be my first contact when I need to pull information from the supplier. I will be able to see sub-suppliers as well and any of their contacts and the responsible staff back home. If I need to call and do some off line communication, I know who to talk to. I can also find the technical documents for this PO. In here I would find all the pin ID’s, the spec sheets, and what have you. I’d also find the supplier data over behind these links. Everything the supplier submitted, instruction manuals, haz built documents, etc. I’d find through here. There’s some other things I could find here. I could log calls or view print reports if I wanted to go fill out the paper on site.

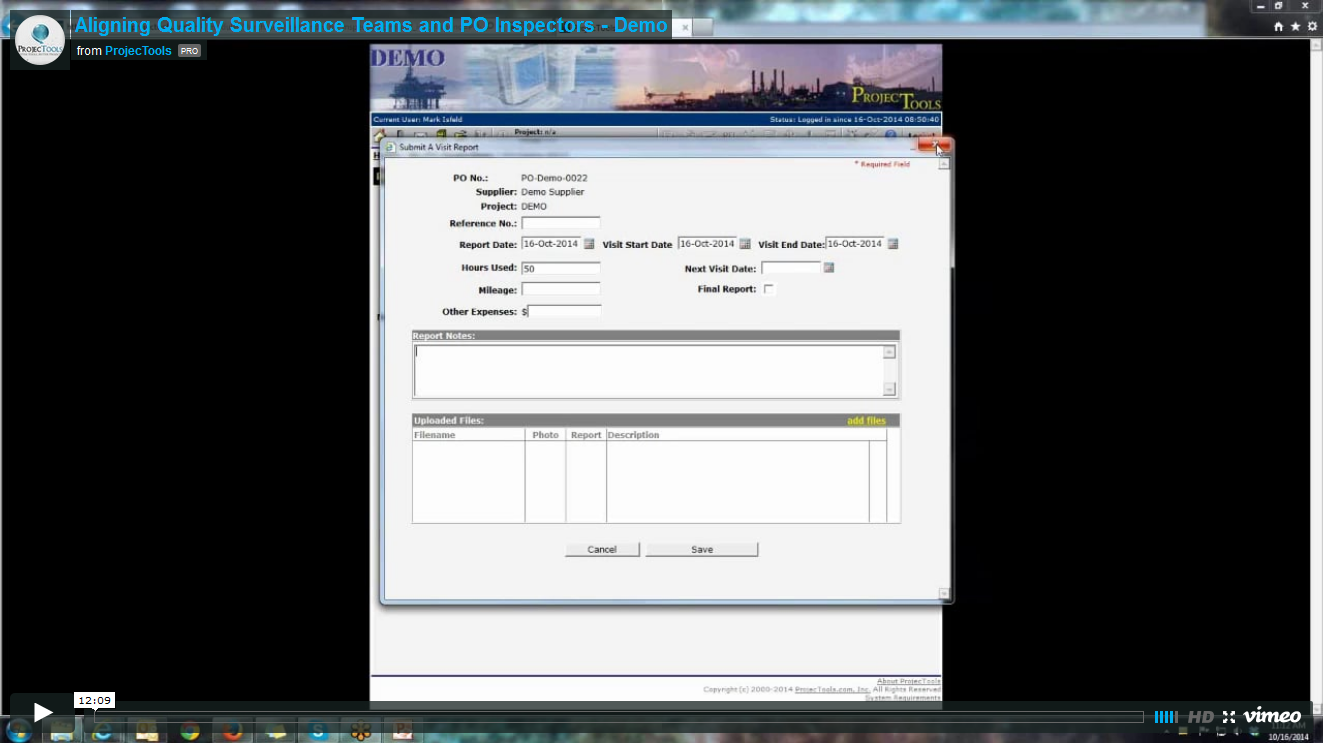

What I really wanted to show you guys today is the submit a site visit report. When I click that button it brings up the screen here. I can enter in a reference number if I have one. I can say what date I’m here at the suppliers facility doing my inspections. I can log the amount of hours used for this particular inspection. Any mileage associated with that and other expenses. I can plan my next visit date. I can put report notes in and upload files. Very common to upload photos. Scan in my notes for my notebook and put them up in here. When I log these results they’re going to float directly back to the Quality Surveillance Team.

The last part of this that really aligns your Inspectors and gets them acting as a team, as your team and advocating for you is the PO supplier performance report. As a part of these reports, when you log these reports, you can issue noncompliance or corrective action reports for your suppliers. If your PO Inspector goes in to inspect a piece of equipment and they’re not allowed on the floor for fifty minutes, they can log that. They can say, “Hey. I went to inspect this thing and they wouldn’t let me on the floor for forty five, fifty minutes. I don’t know what they were doing but it seemed kind of shady.” Your Inspectors can really advocate for you and align themselves with your Quality Surveillance Team.

This is very simple process. Simple module. I hope I proved to you guys today that ProjecTools Quality Surveillance will align your Quality Surveillance Team and Inspectors by getting them working the same system and using a EPC centric work flow and providing a single place for Inspectors to go find the documents and log the results of their inspections.

I want to thank you all for visiting today. I look forward to you guys tuning in next week. We’re going to be talking about Earned Value.

ProjecTools Product Information

ProjecTools Client Spotlight

ProjecTools Client Spotlight "I don't see how companies can manage projects like [...]

Standard Project Management Features

ProjecTools subscriptions provide valuable standard features that support projects. ProjecTools standard features are available to each user to complement core application functions and business processes. Utilize the modules below to increase top-down visibility, communication, accountability

Security and Reliability

Users need a secure, reliable environment to access project information and perform work. All applications and client data resides in a private cloud network with data replication and failover to geographically diverse datacenter equipment. ProjecTools provides 99.5% Network Availability

Construction Project Management Services

ProjecTeams is proven for flexible on-site or remote project deployments. Each ProjecTeam specialist has deep work history with a career of improving project execution, information management processes, with tools that make projects efficient, timely, and profitable.

ProjecTools Resources

Spreadsheets and Email as Project Management Tools

Projects have too many moving parts and too many players to be trusting critical data to spreadsheets and emails. You need a spreadsheet reduction strategy.

Project Management Assessment

Project Management Assessment Assess your project management practices against the best project execution teams in the Capital Construction, [...]

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Aligning Document Control and Cost Control

Align Document Control with Cost Control and create seamless progress and earned value reports to stay on budget and improve cash flows.

ProjecTools Videos, Demos, and Webinars

Optimizing Review and Approval Processes for Engineering

Let’s talk about review and approvals, and closed-loop systems, and how to execute the review and approval processes for engineering and commercial...

The Keys to Successful Document Management

Let's talk specifically about document management software, and the key factors for clean and organized documentation, accessibility, finding a system...

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Document Distribution and Access for EPC and Construction

Global projects have global teams that need to be in the loop. Cloud technology takes the pain out of giving teams on demand access to project data.