Supplier Management for O&G, EPC, and Capital Construction

Suppliers fill a hugely important role in O&G, EPC, Architecture, and Construction projects and supplier performance can affect profitability, schedule, and quality. So the stakes are high in terms of supplier management.

Since it is so important to make sure suppliers perform and deliver on-time with high quality deliverables, buyers and procurement groups should use three key strategies in their supplier management approach.

In the meeting, we will discuss the three strategies and how to implement them, which ultimately will improve accountability, quality, timeliness, and profitability.

Transmittal Management Demo Transcript

Welcome to ProjecTools Supplier Management for oil and gas and construction etcetera. That etcetera on there is any company that has a supply chain where they have to issue bids and manage requisitions and collect bids back from suppliers and manage PO’s or transmit technical documents. There’s a lot of industries that can benefit from the supplier management demo, not just oil and gas construction. Let’s get started here. Let’s talk about some ideas around supplier management that are really helpful and really make a difference for buyers, engineering groups, managers, project managers, etcetera.

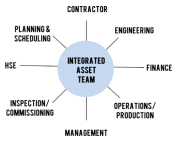

When you have supplier driven project such as oil and gas construction and so forth, having a great supply chain is going to improve the quality of your assets that your building or making, or producing or selling. Part of supplier management is having an effective supply chain and that means effective communication. Where you’re going to start with that is integrating these suppliers into your process. Whatever that looks like for your company, you should think about ways to do it. If you have a lot of engineering and design work, that means integrating the suppliers into the review and approval work flows so you can get their markups earlier in the process rather than later after you’ve issued a PO to working through any issues before they become huge issues and change orders. You can avoid change orders by integrating suppliers in your system. You can also avoid a lot of slips too.

Another thing to think about surrounding supplier management is commercial and technical queries. As you go back and forth, you want to have an integrated approach to managing queries. That doesn’t mean frequent emails back and forth. That means like a totally segmented communication media that will collect all of these queries that go back and forth and segment them per purchased equipment. Having emails going back and forth that reference five different requisitions or PO’s, that’s not very easy to manage and things get confusing. Mistakes get made and then change orders and delays and penalties and poor quality happens. You want to avoid all that if your aim is improving supplier management.

Let’s take a look into some of the problems with supplier management. We’ve kind of talked about the ideal world where your suppliers are integrated into your process and your system and your philosophy, but what are the problems that present themselves as barriers to make that happen? A lot of companies us paper based or electronic systems, relying on pen, paper and manual processes for supplier management. That’s tough because you can’t search for things electronically and it just takes a lot of time. You have to hire couriers to deliver things. That’s totally how people did it 30 years ago. You’d probably think that at least, but some people actually still do that today – and it is a supplier management nightmare. If you can take anything away from this and you’re still doing that, it’s quit using the paper-based supplier management system, get an electronic system that allows you to transmit things instantly and search for items that have gone back and forth. That’s seriously the bare minimum supplier management approach.

he other problems with supplier management is that suppliers give us the runaround. Good or bad, it is what it is. Your suppliers will try and cover their tracks and anything negative that happens throughout interactions or throughout our process, they’re going to try and make it your fault so they don’t get penalized. If you don’t have a good supplier management system to track the communication and what they’re doing and how they’re contributing to the process, and how they plug in, you open yourself up to getting the runaround.

Another supplier management problem is numbering confusion or vision confusion, etcetera. This is just general confusion stuff that a lot of folks go through because they don’t integrate suppliers into whatever sort of system that they use to manage requisitions and documents and so forth. Revision confusion, this is really tougher on suppliers. If they don’t have the latest revision, they don’t know what they’re supplying you, they don’t know what they’re building, et cetera. That’s going to result in change orders and poor quality, or even scraping the whole piece of equipment, or whatever you’re purchasing because it does not work for the application. This is another case of bad supplier management that I see all the time. It has been the norm for so many years that the downsides to this problematic approach to supplier management goes unnoticed.

Among the most painful supplier management problems are that even folks using an application that is supposed to solve supplier management problems can’t really get feedback on drawings, terms, et cetera. They can’t corral a correspondence or get standardized bids back. They can’t make easy comparisons among supplier’s bids in competitive bid situation. You want to have apples to apples bids so you can compare them easily. Finally, the last supplier management problem is it’s very difficult to find a system that will track all of the supplier participation. What they’re doing, give you some visibility into the progress that they’re making and things that they’re doing and make it reportable. When you face all these problems, you don’t have an integrated supplier network. Your supply chain is operating purely based on chance and the good will of your suppliers. Let’s take a look at some things you can do to fix this and break the problematic supplier management practices. This is not earth shattering stuff. It’s all actually pretty easy to implement. Let’s go take a look at some of these real world things.

The best solution to solving these problems is getting suppliers and subs working in your system. This should be pretty obvious. If you don’t have a supplier management system or an application to manage these things, go get one. There’s a lot of really good ones out there. We have one. I’m going to show it to you here in a little bit and how we manage all this. Number two, you want to get suppliers and subs working as a part of your team. You want to integrate them in everything that you reasonably can. If it makes sense to include them on a review and approval, do it. Treat them like part of the team. Ask them for their opinions. If they supply something to you, chance are that the supply it to somebody else. They really know that area and they have expertise, in a detailed level of expertise that you guys might not have. It’s really good to pick their brain systematically.

The third thing is move the interface of suppliers into a single system as some work flows. I mentioned email before and even couriers, send letters and so forth. Don’t do any of that. Pick that application, integrate them into your software system and then make sure all of the interactions happen within that system. Even one step further, segment all of that interaction based on the requisition or the PO that the correspondence is about. Number four, you want to have accountability and visibility so things get done. This is pretty obvious with an email based system where you’re just shooting emails back and forth, or phone calls, or couriers, there’s a lot of time lapse there. The suppliers are sending you what they think you want to see in an email. They can build this façade of things that are going perfectly, but if they’re working in your system as a team member, you can really see the progress that they’re making and the things that they’re doing. You’re not going to have some sort of Wizard of Oz situation with the guy behind the mirror, who’s not actually anything special.

Now I want to take you in to look at ProjecTools application. The first thing I want to show you is ProjecTools Supplier Manager. This is just basically a directory. Let’s take a look at one particular supplier. We allow you to manage a bunch of information about the suppliers here. You have their basic info, their regions, the services they offer, commercial codes, PO descriptions that they’re approved to handle, manufactures that they work with and contacts within the companies themselves. Let’s take a look at this. You can have the individual contact’s address. You can make them user logins. I’m going to show you the interface that they see and how they interact with your company here in a minute.

You can see the open tasks that they have that haven’t been done. You can see when they’re due, so you can really maintain some accountability in here. We can see that this supplier data Transmittal hasn’t been responded to in two years here, but the other one, they’re on track with this requisition. You can also see requisitions that are assigned to this particular contact and PO’s and so forth. You want to have a nice system like this where you can have some sort of rating system as well, to judge your suppliers on. Rating and ranking your suppliers based on an empirical system.

Basically just use your supplier management scoring system and then convert useful datapoints into a score and put it in here. You can also keep track of whether this supplier’s qualified or not qualified. This is good supplier management, especially if you have unqualified people that keep trying to bid on your stuff. You can quickly go and see that they’re not qualified for whatever reason so you don’t have to waste a bunch of time trying to see if they meet the mark. You’ve already done the work, why do it twice?

The next thing I want to show you is the supplier side of supplier management, what your suppliers see and how they interact with your projects and your data and so forth. This is that supplier we looked at and those are the few things we say this task is late from two years ago. This one’s on time. I’ve built a requisition and the back end on the buyer’s side. I issued it out to this particular supplier for them to bid on it. Let’s take a look at what that looks like. Right away, we can see there’s a bunch of information and when this thing’s due. That’s important. We can also see that there’s an acknowledgment, so if the supplier opens it up, they can acknowledge it formally. The acknowledgment flows back to the buyer. They can see all the notes to bidder, instructions to bidder. This is a simple PO, so it doesn’t add any of that. They can access the technical documents here, they can download them. They can see any of the document histories of the new revs for this. They’ll see that here. This is a pretty automated thing, same thing with commercial documents. When your suppliers have crystal clear instructions and an intuitive way to interact with bids and such – supplier management will be exponentially smoother. When issues come up – you can come back with “Mr. Supplier, log in to the system and read the instructions.”

Finally, we get down here to the bidder intention. After, note, after they’ve acknowledged it and downloaded the technical documents will all them to issue an intention so they can either say yeah, or no. After they submit that RFQ intentions, they can go down here and start working on the bid sheet. It’s a work flow here. We want to make sure that yes they got it and yes they downloaded all the documents, yes they’re going to bid on it before they actually start filling out the bid. It’s a good process and a work flow and that makes sure your suppliers are doing these things in the correct order. Even in a sealed bid situation, the buyers can go in and see what kind of progress the suppliers making on a bid without seeing details, like prices. Finally, when the bidder’s done here, they just submit this bid and it goes back to the buyers. If it’s a closed bid it’ll just sit in the que, closed and somewhat hidden until all the bids are in.

The next thing I’m going to show you here is purchase orders. Obviously, this demo supplier gets a lot of action here. Let’s go take a look at this PO here. After you’ve issued a PO to a supplier, they can go in and do some things. They can view PO, via the relevant context, either of data requirements that we’re going to need back from them for the PO. The cool thing here is they can submit supplier data directly from the application and it flows to our document management module. It really removes a lot of steps. If the supplier has to email something to your document controller, there’s that initial email from them. The document controller has to go log everything. Inevitably, something’s wrong. They didn’t attach something, or they attached the wrong file, or the wrong revision or they didn’t name it correctly. This takes care of all that. They just go in and they add files from their little application here.

The other thing worth noting here is the request response system, this is for technical and commercial queries. They can initiate them on the supplier side and then they can respond to the queries if they get them. If they’re responding to them they’ll show on the home page as a task. Speaking of tasks, take a look at this transmittal. This is a task that’s been sent out to this particular supplier. They’ve basically just been copied. We sent a document to a client for either delivery or review and approval. We copied them on it saying, “Hey, your documents been sent out to our client.” They’ll get any feedback that the client’s come up with as well. You can also issue a review and approval task so they can actively participate in it rather than just getting copied on correspondence. Even if they don’t use your type of files they can use the integrated mark up and review tool to actually participate even if they don’t have the same cad software. Suppliers generally like that because some of that stuff’s real expensive.

All right, so I’m going to log out of here and I’m going to go and show you what it looks like on the buyers side. I’m going to find my requisition here that we’ve been looking at, the one that was issued out to the bidder we just took a look at. After this thing’s been issued to the bidders we can come in here and we can see some different things. We can see that they’ve been issued online, that a couple of these folks have acknowledged it. Oil Fields Supply, which is the one bidder we were logged in as, they have not acknowledged R of Q. We can go in here, we can drill down the information a little bit. We can see that they acknowledged it and if they’ve indicated a bid or no bid and when they said they’re going to get a quote back to us by. We can see any extensions that we’ve done here. We can see if they have asked for extensions or if we’ve just given it to everybody. Over here in the history we can see that I’ve just extended the bids arbitrarily, just to show you what’s going on and how to use the tool.

Finally we can save the bids actually have been submitted and we can mark them as received. After we’ve done that we can take a look at the actual bids themselves. Basically what I’ve showed you here is ProjecTools gets suppliers and subs working in your system. Suppliers and subs, they can really work as part of the team. They can be integrated using your application, which makes them feel more a part of a team and allows you to leverage their skills, their detailed skills more effectively then you can with emails, phone calls and smoke signals, whatever you’re using now. You can really focus them on the things that are going to help you out rather then letting them run wild and give you the runaround possibly.

You’ll notice that we’ve moved all of the interface with this particular supplier into a single system and then there’s some work flows to it. They have to move in a single, predetermined order to get things done. We can kind of report back on that without seeing sensitive things like prices until we’re meant to see it. There’s also accountability, this ability built in so you can report on things. You can run late action reports and see who’s not getting reviews back to you, who’s not submitting their supplier data on time. Just things like that, where you’d have to just know in your head or look at a schedule and be like, “Hey, do we have x document from the vendor or the supplier?” Then go in and look at those individual basis. ProjecTools gives you the ability to click a button and then it’ll just tell you everything.

That’s really the benefit of having a system that integrates everybody and has accountability and disability built in because you can get things done. You can get them done quickly. You can get them done right. Your qualities better. You don’t get penalties. You’re delivering on time and everybody knows what’s going on and everybody’s happy. The end result there is you’re going to get repeat business from your clients because they know that your supply chain is good and you have your stuff together and you can get things done.

ProjecTools Product Information

ProjecTools Client Spotlight

ProjecTools Client Spotlight "I don't see how companies can manage projects like [...]

Standard Project Management Features

ProjecTools subscriptions provide valuable standard features that support projects. ProjecTools standard features are available to each user to complement core application functions and business processes. Utilize the modules below to increase top-down visibility, communication, accountability

Security and Reliability

Users need a secure, reliable environment to access project information and perform work. All applications and client data resides in a private cloud network with data replication and failover to geographically diverse datacenter equipment. ProjecTools provides 99.5% Network Availability

Construction Project Management Services

ProjecTeams is proven for flexible on-site or remote project deployments. Each ProjecTeam specialist has deep work history with a career of improving project execution, information management processes, with tools that make projects efficient, timely, and profitable.

ProjecTools Resources

Spreadsheets and Email as Project Management Tools

Projects have too many moving parts and too many players to be trusting critical data to spreadsheets and emails. You need a spreadsheet reduction strategy.

Project Management Assessment

Project Management Assessment Assess your project management practices against the best project execution teams in the Capital Construction, [...]

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Aligning Document Control and Cost Control

Align Document Control with Cost Control and create seamless progress and earned value reports to stay on budget and improve cash flows.

ProjecTools Videos, Demos, and Webinars

Optimizing Review and Approval Processes for Engineering

Let’s talk about review and approvals, and closed-loop systems, and how to execute the review and approval processes for engineering and commercial...

The Keys to Successful Document Management

Let's talk specifically about document management software, and the key factors for clean and organized documentation, accessibility, finding a system...

Document Management Software ROI

Document management is massively important for engineering and construction projects. Take the approach and use the tools that add the most value.

Document Distribution and Access for EPC and Construction

Global projects have global teams that need to be in the loop. Cloud technology takes the pain out of giving teams on demand access to project data.